So You’re Almost Sure You Wanna Do This…

If you’re reading this, chances are that you’re mostly sure you want to go the RTA (ready-to-assemble) cabinet route for your home remodel/renovation.

You’ve seen the gorgeous results others have shared online. You’re definitely drawn to the cost savings. And you’re not afraid to roll up your sleeves and do the work yourself.

But there are still lingering questions in the back of your mind.

Will I actually be able to pull this off?

How much skill does this really take?

Is this going to look like a cheap mistake when I’m done?

You’re not alone.

I was in the exact same boat. I wanted high-quality, custom cabinetry without blowing my entire budget. And I wasn’t interested in anything flimsy, low quality or mass-produced.

I have a Cabinet Joint discount code to share with you! Email me at [email protected] and I’ll send it to you!

I’m a Professional: Well, Let Me Explain…

I’ve been a professional cabinet painter for over a decade. In that time I’ve painted cabinets in hundreds of homes.

I’ve seen it all; from the most painfully obvious DIY missteps to high-end, custom-fitted cabinetry that costs more than some people’s mortgages (no, seriously).

So, I’m not a professional carpenter or a cabinetmaker. However, when it comes to cabinetry construction, durability, and finish quality, I’ve developed a trained eye.

So when I say Cabinet Joint offers some of the best cabinetry I’ve ever worked with, I say it from a place of real, hands-on experience.

The Brass Tacks…

My goal with this post isn’t to persuade you that building and installing your own cabinetry is the right choice for everyone because clearly, it’s not. This path requires time, patience and a willingness to learn as you go.

What I do hope, is that sharing my honest experience working with Cabinet Joint, helps you feel more confident in your decision to go the RTA route.

If you’re already leaning in this direction, maybe my perspective can offer some clarity and make choosing the right company feel a little less overwhelming.

Without further ado, here’s my Cabinet Joint review. Op, I rhymed.

This post is written as part of a partnership with Cabinet Joint, all experiences and opinions are my own.

Why I Chose Ready To Assemble (RTA) Cabinets

When my husband and I decided to embark on a full-home renovation, I knew one thing for sure: one of my non-negotiables was custom kitchen cabinets. But I ran into a couple of issues right off the bat.

First issue, there were no cabinet shops or cabinet carpenters local to me who offered beaded frames and flush inset cabinet doors. In order for me to get the style I wanted, I’d have to source shops farther away which just added to the bottom line.

Second issue, custom cabinets are freaking expensive!

I get it, I’m not saying that the price isn’t justified. I’m just saying that I couldn’t afford exactly what I wanted.

But one thing about me, I hate to settle for anything less than what I want. I do all I can to make it happen. Sometimes that means you gotta invest some sweat equity.

When I learned that Cabinet Joint offered custom beaded frame, inset cabinetry AND it was within my budget but it meant that I had to assemble, install and paint them myself…say less. Where do I enter my payment info?

In case you’re unsure what “beaded cabinet frame with inset doors” looks like, here’s a photo.

Why I Think Cabinet Joint Makes the Best RTA Cabinets (and what you need to know before you order)

I did a lot of research on RTA cabinetry before finally decided on Cabinet Joint. Some of my favorite Instagram accounts used Cabinet Joint in their homes and documented the process with their audiences. It was so nice to watch a real person go through the assembly and installation process in real-time.

Seeing their final results sealed the deal for me. If I hadn’t watched them with my own eyes during the process, there’s no way I would’ve guessed they were RTA cabinets.

Here are a few cabinet photos from the accounts I followed.

Above: The Renovation Husband’s Kitchen blows me away. Y’all, these cabinets came in flat-pack boxes! Tell me that doesn’t look like they spent $150,000 on custom-built, on-site cabinets! It’s so good.

Above: My internet friend, Erin Zubot, used Cabinet Joint for her primary bathroom vanity. It looks so great. Her blog post here also has more info on their assembly and installation process.

Above: And lastly, Christine used Cabinet Joint in her recent kitchen remodel, too. It looks amazing! Like I said, you’d never guess that these cabinets weren’t custom-made by a skilled carpenter!

Unmatched Customization

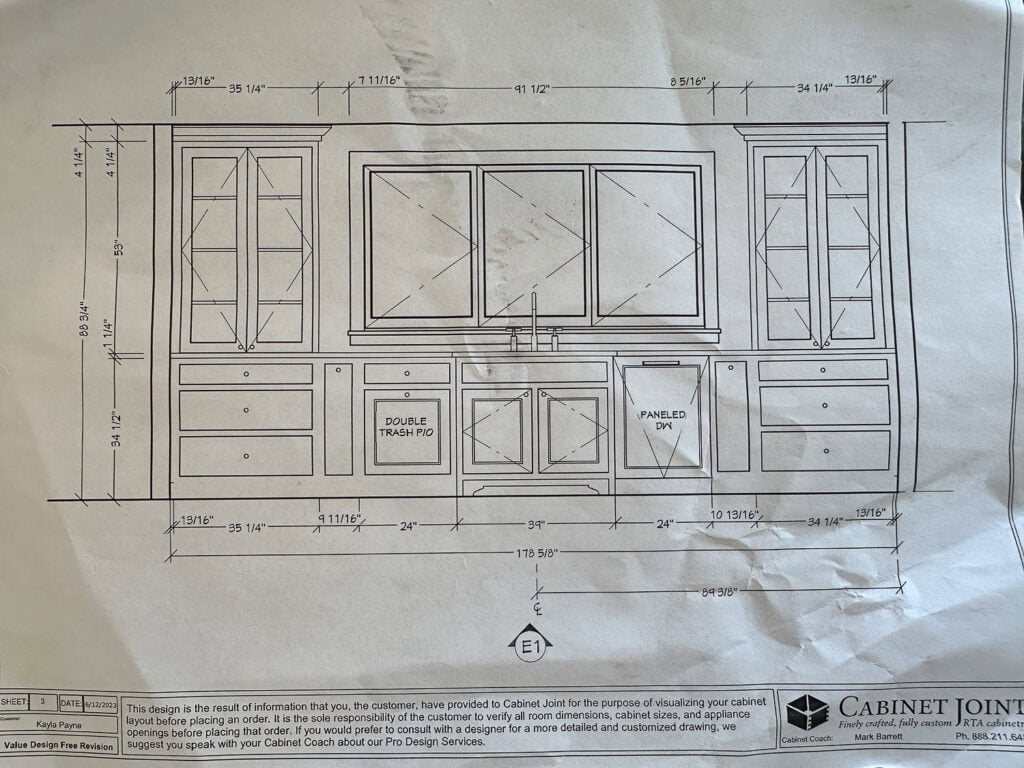

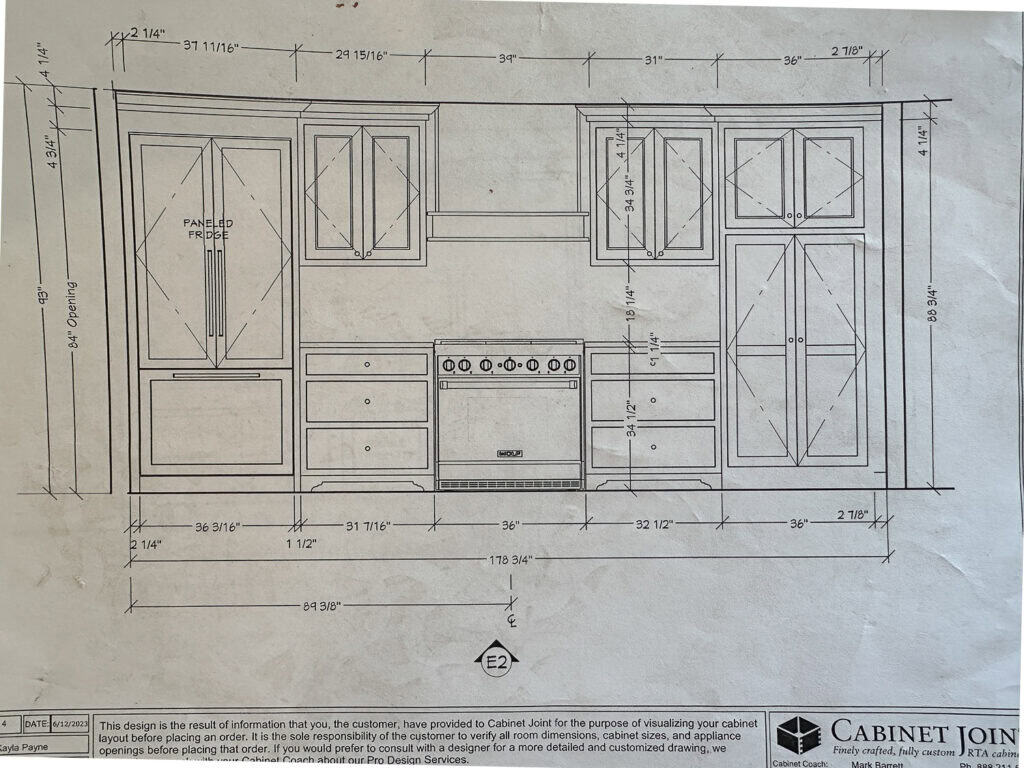

One of the biggest advantages of working with Cabinet Joint is how customizable their cabinetry is. We’re talking down to 1/16″ increments. That level of precision allowed me to make every cabinet fit perfectly into our space without having to utilize filler strips.

Filler strips are often a clear sign that the cabinets weren’t custom-built and are typically associated with lower-end installations.

I loved that I was able to purchase my cabinets “unfinished”, meaning not painted.

Since I’m a cabinet painter, this was a no-brainer and a great way to save even more money.

PLUS, I wanted a custom, high-gloss cabinet finish that isn’t offered anywhere or by any RTA company. It was a paint finish I had to do myself no matter what.

However, if the idea of painting or staining your own cabinets makes you ill, no worries. Cabinet Joint offers a wide array of paint colors and stains plus the option to upgrade to whatever custom color you desire.

Premium Materials – No Particle Board, Ever

Another selling point for me was Cabinet Joint’s commitment to quality materials. There’s zero particle board used in any of their products.

Everything is built from solid wood, furniture-grade plywood, medium density fiberboard (MDF), and real-wood veneers.

In case you didn’t know, these are the exact materials any quality, custom cabinet shop would use to build your cabinets.

I was shocked to see how many wood species they offered, too.

I chose Natural Mahogany for my island. Maybe it’s just because I live in a small, rural town in Arkansas, but I have never known of anyone being able to request Mahogany from a cabinet maker.

Top-Tier Hardware and Construction

Cabinet Joint cabinets come standard with Blum soft-close hardware, including both hinges and full extension drawer slides. Blum is the gold standard in cabinet hardware. They’re smooth, quiet and built to last.

All drawers feature dovetail joinery. I was so happy when all our drawer boxes came pre-assembled too!

I was under the impression that I’d be building the boxes along with everything else. All I had to do to assemble the drawer boxes was attach the drawer catch mechanism to the underneath side and screw the drawer face to the drawer box.

A huge bonus, these cabinets are 100% Made In America!

Support When You Need It: Your Very Own Cabinet Coach

Here’s where Cabinet Joint really sets themselves apart: they don’t just drop pallets of cabinet parts at your door and wish you luck!

Every customer is paired with a dedicated “Cabinet Coach”. This is someone on their team who knows the ins and outs of the system and can guide you throughout the entire process as much or as little as you need.

If you’ve already checked out the Cabinet Joint website, you’ve noticed that it’s loaded with A TON of information, options and details.

This is a good thing, but it can easily become overwhelming in a hurry. And nothing makes a person shut down and say “NOPE” faster than becoming overwhelmed.

This is where your cabinet coach is invaluable. Their job is to answer all your questions, make recommendations and simplify the cabinet designing process.

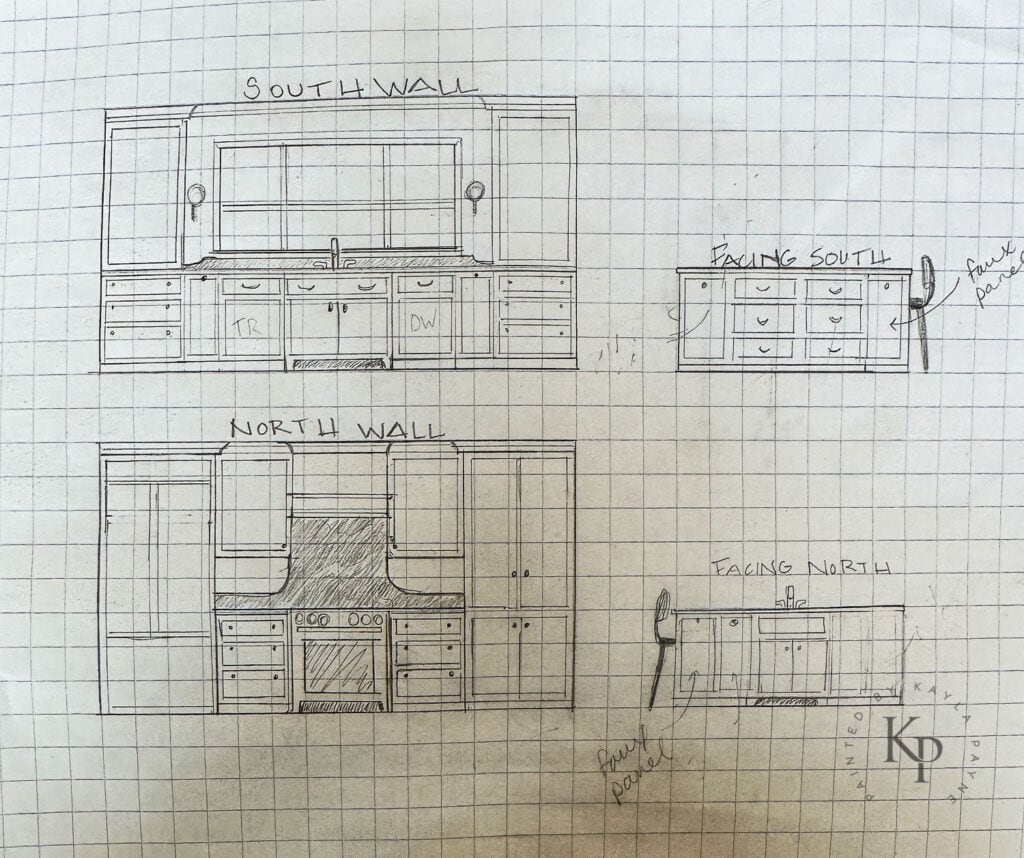

My cabinet coach’s name was Mark. I lost track at how many emails we exchanged in the months leading up to my final purchase! He took the time to walk me through each cabinet unit I selected.

I also appreciated that we were able to do a face-time chat before I signed off on my order. We walked through every single line item on my order! Every.single.line.

How Much Skill Is Required To Assemble RTA Cabinets?

This is a great question, and one that should not be overlooked before purchasing ready to assemble cabinetry. RTA cabinets require some level of skill, but it’s more about patience, attention to detail and willingness to just do it.

Here’s a breakdown to help you self-assess if DIY RTA cabinets are the right fit for you:

- Beginner to Intermediate DIYer: If you’ve used a drill before and can follow video-based tutorials then you’re certainly capable of putting these together! I assembled all of our kitchen cabinets in less than 2 weeks. I did it mostly on my own, but I did have my husband’s help for the large boxes (ie: the fridge and pantry cabinets)

- Tools Required: Typically you only need a drill, rubber mallet, clamps, wood glue, finish nailer, maybe a pin nailer and air compressor to run those tools (unless you have battery powered). If you’re assembling inset cabinets, this tool is a must for installing the hinge plates to the face frames!

- Time Commitment: An average size cabinet takes around 30-45 minutes to assemble at first, but that time lessens as you go!

- Precision Matters: These aren’t slap-it-together cabinet boxes. Cabinet Joint’s cabinets are high-quality and precision-engineered so you really need to put them together accurately and ensure things remain as square as possible!

- Installation Is Not A Cake Walk: While the assembly is honestly a breeze, the real work begins when it’s time to set the cabinets! A lot of people choose to hire a professional at this point in the process, and that is a fine idea! I’d rate installation as an advanced DIYer and above! My dad helped me a lot during my installation. Or, I guess I should say, I helped HIM during our install. He’s had cabinet installation experience in the past which came in handy for sure.

Things That Help Make It Easier

- Cabinet Joint’s Resources: They offer a full library of video instructions on their website and YouTube channel – this is an invaluable resource. I watched their tutorials on several occasions. Your cabinet coach is a phone call or email away!

- Pre-Drilled Components: This one was my favorite! Most of the holes are marked or slightly pre-cut to show you exactly where they need to be which saves you from HAVING TO MEASURE ALMOST ANYTHING!! This truly made things soooo easy. If you’re worried you’ll have to be intimately familiar with the 32nd mark on your tape measure, this will be music to your ears!

To Finish or Not To Finish? That is the Question

Like I mentioned earlier, I paint cabinets professionally, so ordering our cabinets un-finished was the best option for me. This allowed me the opportunity to save more money and paint them exactly how I wanted to.

Cabinet Joint strongly suggests to use doors and drawers made of MDF if you’re painting them. I wasn’t sure at first because I’ve always thought that cabinet doors constructed of wood are superior. However, MDF for paint-grade does make a lot of sense.

MDF is more stable than wood which means it isn’t as susceptible to temperature and humidity fluctuations; therefore it won’t move like natural wood does.

Natural wood moves so much – a shocking amount really. When the wood of a painted cabinet door shrinks, it can reveal a bit of the un-painted part around the panel. It will drive you crazy.

So far, I’ve had zero movement from my MDF doors! So, I’m very glad I chose to follow their suggestion and went with the 5-piece MDF doors and slab drawer fronts for my paint-grade cabinets.

All of my paint-grade face frames are made of solid maple.

Final Thoughts: Are RTA Cabinets Worth It?

Hands down, without a doubt, using RTA cabinets was one of the best decisions we made during our renovation.

Using Cabinet Joint made it possible for me to achieve the kitchen of my dreams on a realistic budget.I will be using them again in the future for my primary bedroom wardrobe and our bathroom vanity.

The End Result: How Our RTA Cabinets Look

I’m so happy with the way they turned out, and pretty darn proud of all the work we did ourselves too! More of my kitchen sources can be found in this post.

Now, I understand that high-gloss cabinets are NOT for everyone. Yes, this is extremely “taste-specific”, but please allow me to go on a short tangent…

As a professional painter, I can tell you that achieving a high gloss finish is very difficult – I think this is probably common knowledge.

So even if you dislike the high sheen, and even if you detest the shade of green I chose, I hope that you can at least appreciate just HOW GOOD the cabinet substrate quality has to be before one can apply a gloss paint to it.

Believe me when I say that the fact that I was able to 1) Order these cabinets online 2) They were shipped hundreds of miles to my doorstep 3) I put them together with my two hands 4) I installed them with help and 5) After all that I was able to paint them in a high-gloss finish that turned out *so good is kind of mind blowing!

Maybe that’s only mind-blowing to me because I’m very familiar with cabinets and painting due to my job – but hopefully I can convey to you how big of a deal this is.

Ok I’m done with my tangent.

Leave a Reply